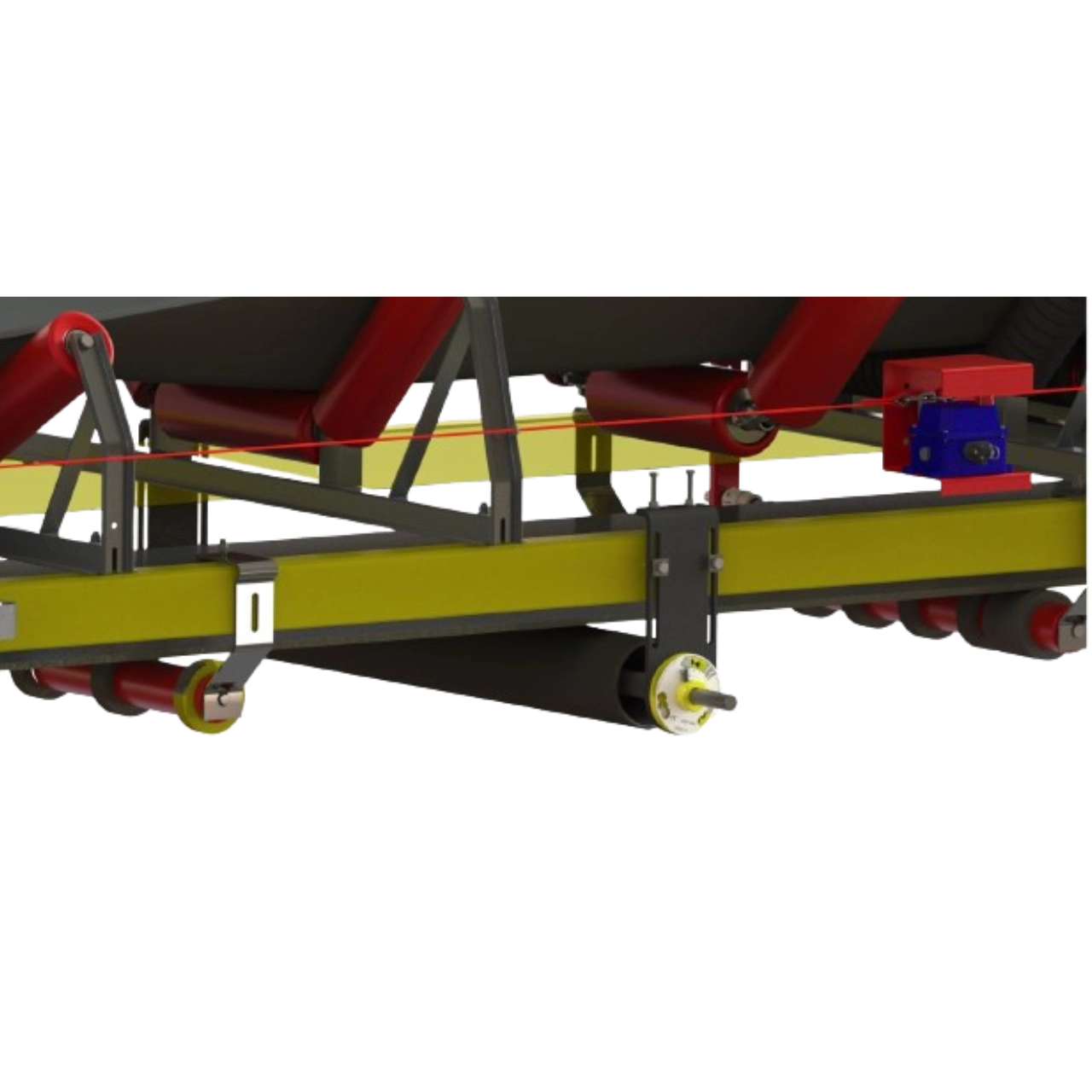

HX270 Belt Condition Monitoring

Real-time Optical 3D Belt Surface Scanning

The Belt Condition Monitoring System monitors the belt by using material and clean side monitoring modules located in the optimal position in respect of reaction to the belt damages. The loading and unloading points are the most critical positions of the belt conveyor to get the belt damaged.

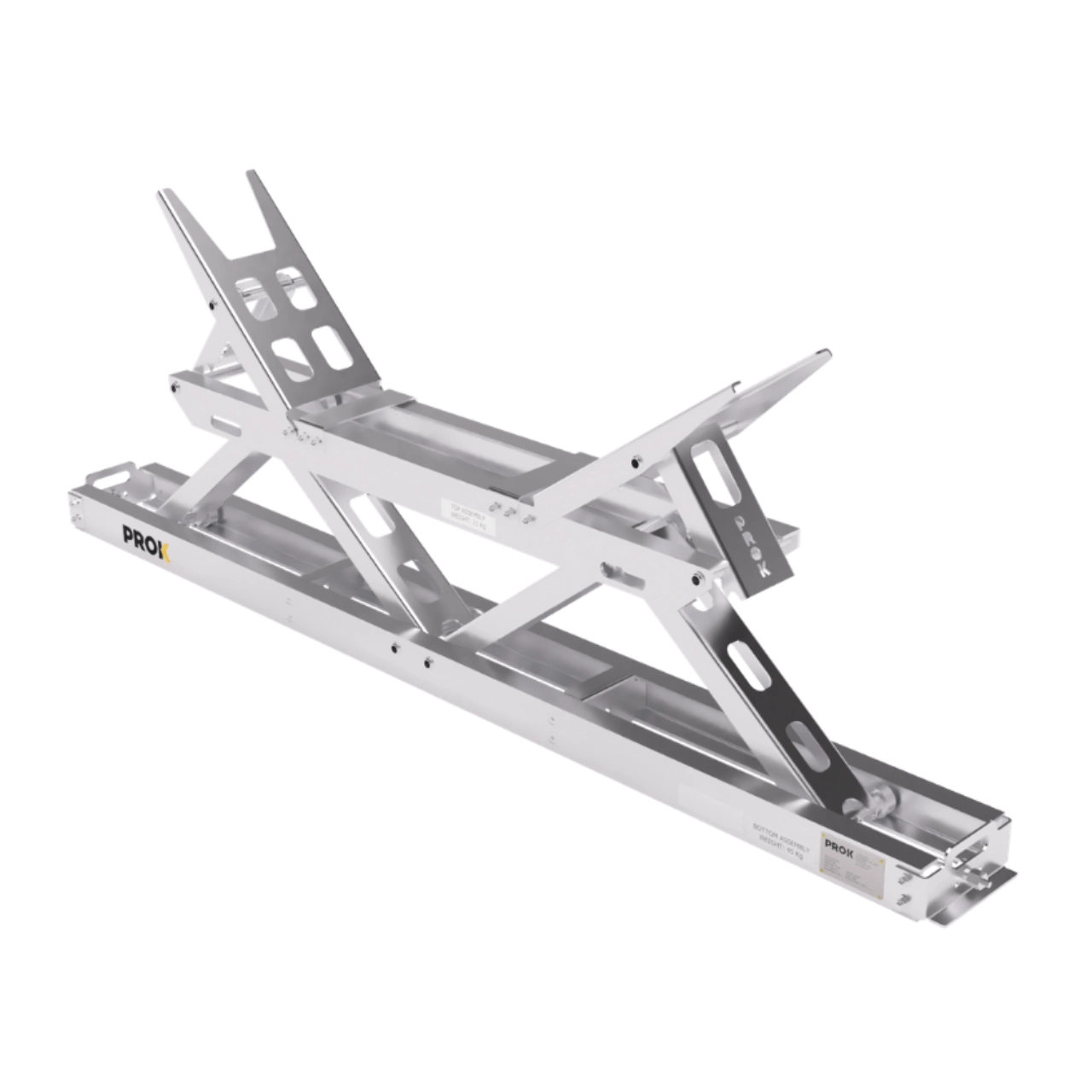

HX170 Belt Condition Monitoring

HX170 Belt Condition Monitoring System is a compact package designed with adaptability in mind. It is designed to detect all damages that happen to the surface of conveyor belts avoiding production loss and ensuring safety.

Belt Condition Monitoring System Features

Belt Condition Monitoring System Features

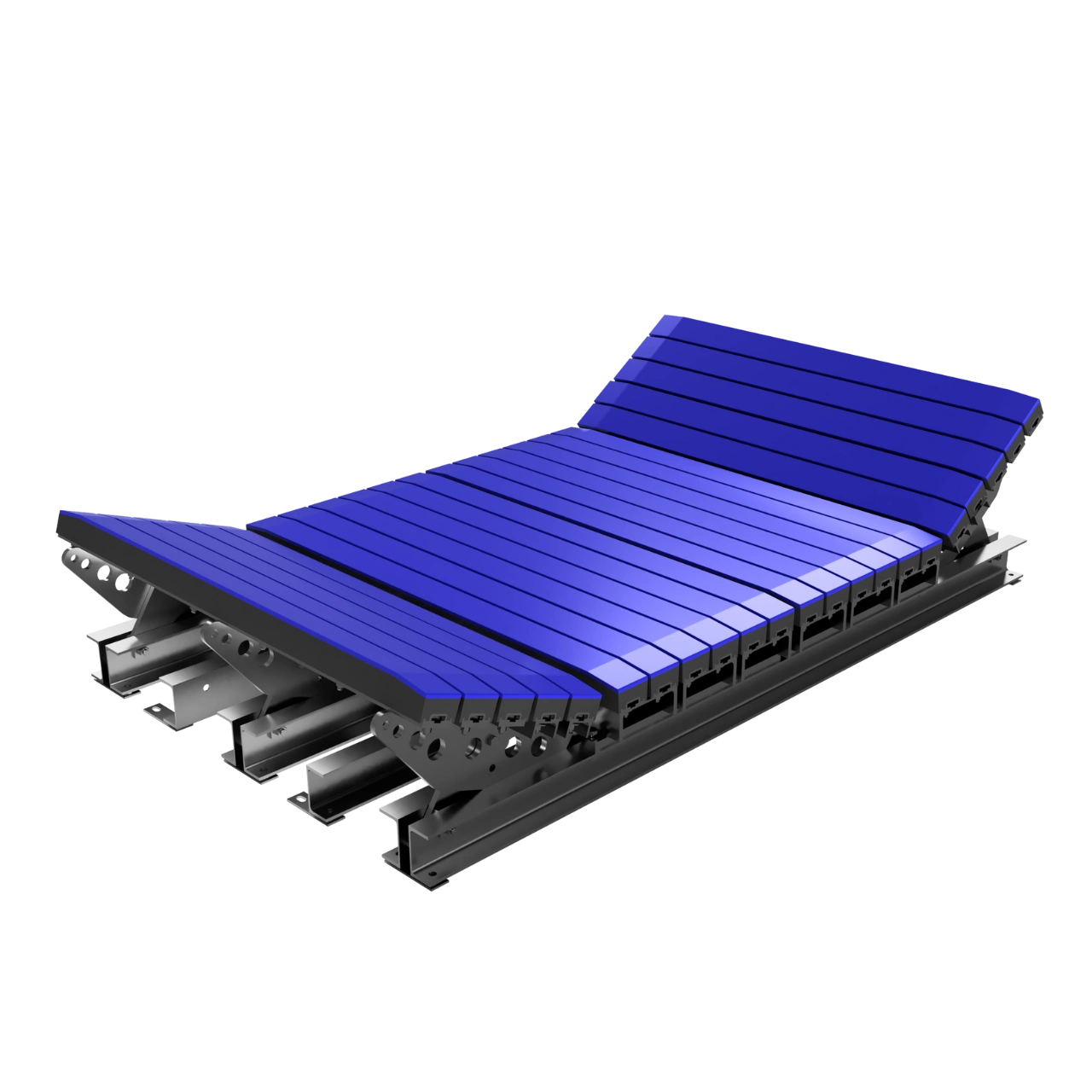

Reduce Belt Repair Costs

- Identify faults early and repair them before they become severe and require significant plant downtime and expenditure to repair

Maximise Belt Life

- Repair Belt Damage before the fault affects the integrity of the belt carcass

- Detect Belt Rips quickly and reliably, with an automated response that limits the extent of damage

Reduce safety risk and environmental impact

- Automated Monitoring Systems such as PROK’s HX270 greatly reduce the need for Field Belt Inspections

- Reduces the Risk of a Catastrophic Belt Failure, and Uncontrolled Belt Movement

- Less Belting is sent for Recycling or Landfill as Belting more often reaches it’s Service Life

View more accessories

Don’t get left behind

We don’t stop chasing performance, and neither should you. Optimise your site today.