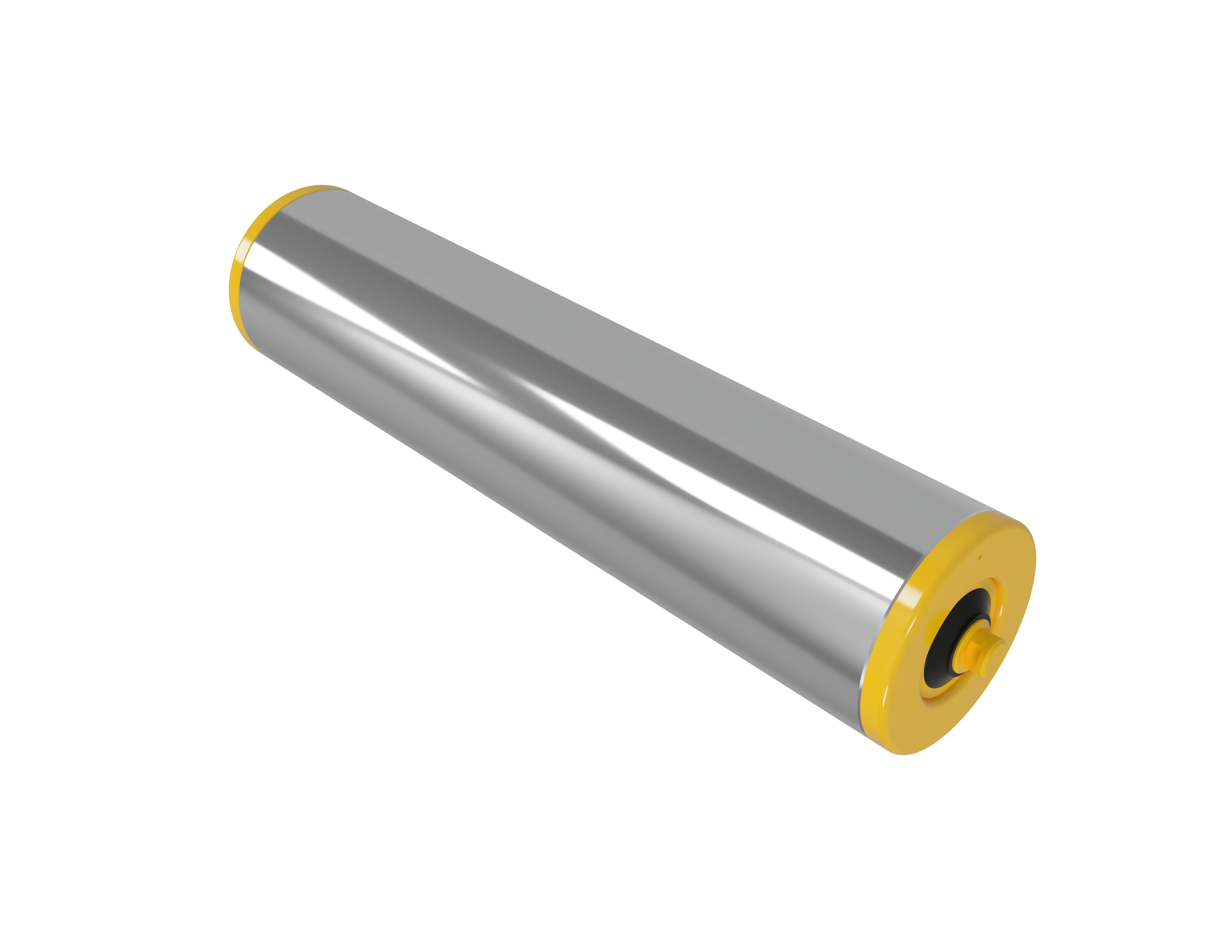

Formed Steel Rollers designed for advanced performance

Our Formed series rollers are manufactured using a unique flow forming and end forming process to create a one-piece steel roller without welding.

The roller shell ends are formed into bearing housings and bored for accuracy, resulting in aligned bearings and an extremely reliable roller for high speed, high tonnage applications. This roller is used on some of the world’s largest conveyor belts and has a proven track record at high speeds (52,000 TPH @ 11m/s).

Formed rollers are available as carry, impact and return rollers as well as garlands.

Formed Steel Roller Benefits

- Forming avoids the need for dynamic balancing and machining, allowing high belt speeds.

- Suitable for conveyor loads up to 52,000 mt/h and belt speeds up to 11 m/s (36 ft/s), achieved by a reduction of vibration which also reduces noise emissions.

- Exceptional roundness, straightness and hardness; inherent balance G<16 according to DIN ISO1940, maximum concentric deviation maximum 0.3 m.

- Also available with shell wall thickness increased at the center of the roller to reduce shell stress and deformation.

- The hollow formed shaft offers an extremely high bending resistance combined with the relatively low weight.

- Hollow shaft and optimized shell thickness with lower weight enables easier and safer handling.

View more rollers

Don’t get left behind

We don’t stop chasing performance, and neither should you. Optimise your site today.