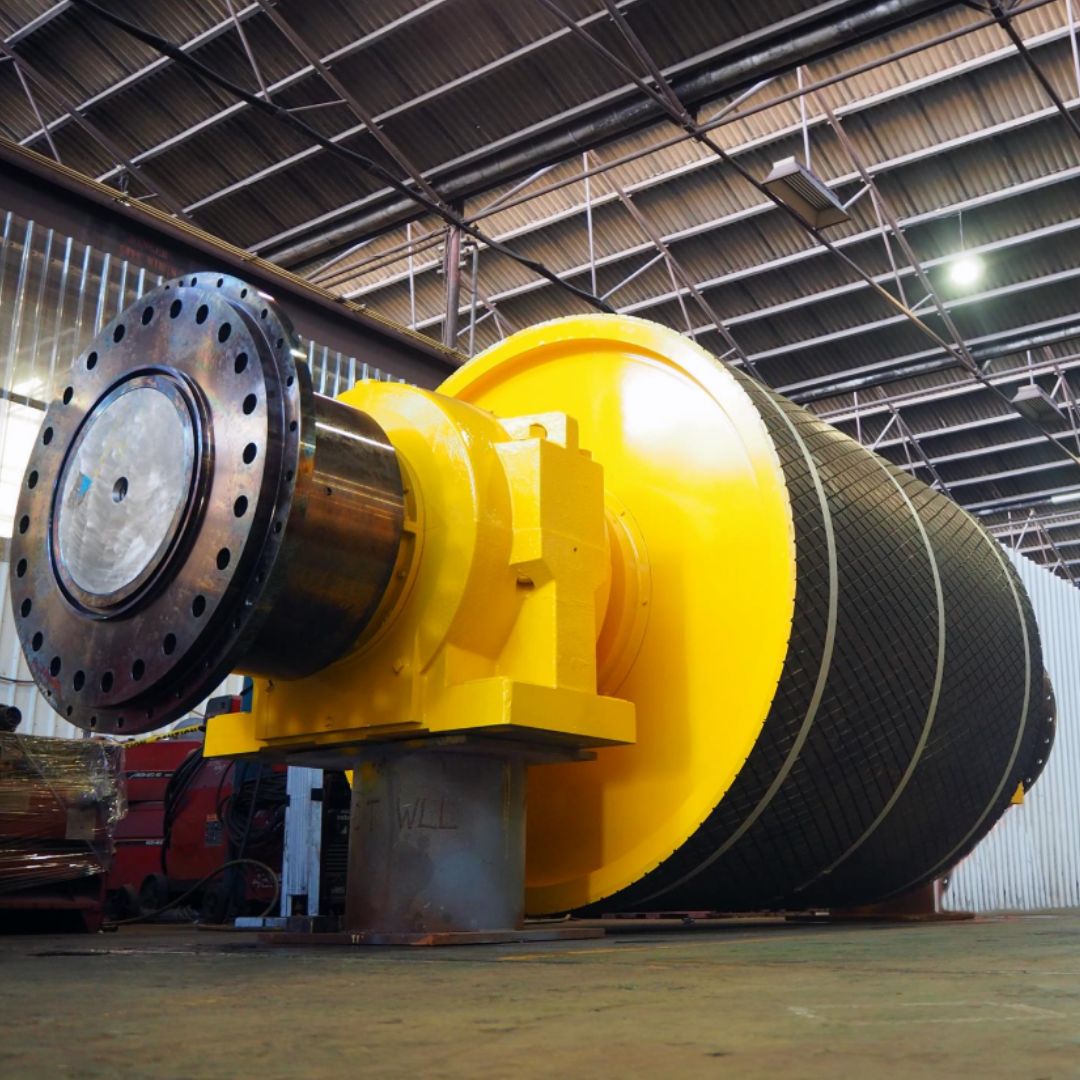

All equipment components are engineered in some way, however, the term “engineered product” is used to describe something tailor-made. When applied to conveyor pulleys, ‘engineered’ means designed specifically to meet the conditions of a particular conveyor.

When done right, the result is a pulley designed for infinite fatigue life with the lowest capital cost for the application and a quality build to ensure customers get benefit in both Capex and Opex.

Investing in quality engineered pulleys makes good business sense for mining companies. They ensure increased safety, lower weight, longer life and improved reliability.

“Once the belt stops, production stops – and mining companies can lose millions each year,” said Craig Wilson, PROK Vice President North America.

“With only one pulley failure the whole belt must stop and, in some cases, all production for the mine ceases meaning that investing in quality engineered pulleys is a very important decision for mines seeking to reduce overall costs and improve production” he added.

Besides unsafe pulley failures can have catastrophic consequences and take extended periods of downtime to repair. Understanding dynamics, engineering out potential failure points and adding in processes for safety are basic concepts, however, many pulley manufacturers forgo these in favour of lowering costs and adding more to their throughput than yours!

“PROK focuses on innovation, quality and your up time. Backed by years of experience, significant investments in research and a reputation among clients for having best-performing products, PROK puts quality and reliability at the forefront of engineered pulley design” said Mr Wilson.

Advanced Manufacturing

PROK engineered pulleys are built for infinite fatigue life. They’re manufactured in state-of-the-art CNC facilities located in major mining markets across the globe, with ongoing operational and maintenance services provided by local engineering teams.

Each year PROK produces around 3000 engineered pulleys in a wide range of diameters and lengths to suit all applications.

Building and Rebuilding

PROK is so focused on your needs that it designed and built pulley acceptance testing equipment for its major facilities. This equipment dynamically engages pulley assemblies and tests them prior to leaving the facility, meaning when you purchase from PROK you are making an investment in reliability and productivity for your materials handling requirement.

PROK also has the capabilities to dynamically balance each pulley, better ensuring uptime and giving peace of mind for hard to reach pulleys.

PROK engineered pulleys come on steel cradles intended not only to transport your pulleys safely to site but be kept for when they need returning to a PROK service center for refurbishing and recertifying.

The PROK Difference

Designed with years of industry advancement and infinite fatigue life criteria, PROK aims to maximise your uptime and reduce total cost of ownership.

“Buyers might not save money when purchasing a PROK engineered pulley, however, they will save on total cost of ownership” said Mr. Wilson.

To find out how PROK engineered pulleys can boost your uptime, lower your total cost of ownership and deliver you a higher ROI, head to prok.com/contact.