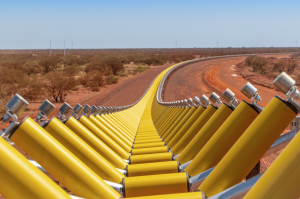

One of the world’s leading and most innovative miners has turned to PROK for conveyor components on its new overland system.

As part of their ROM4 mine expansion, Roy Hill constructed a new overland conveyor system totaling over 8km in length. PROK was selected to manufacture and supply the idlers for the new system.

PROK was awarded the contract for the conveyor idlers off the back of a long history of success with various overland conveyor systems across the globe.

Roy Hill required the new overland conveyor to connect a new crusher to the existing mine infrastructure. The system comprises 2 overland conveyor systems approximately 8km in length.

The entire project scope for the conveyor components included the manufacture and supply of 23,500 rollers and 6,500 idler frames.

The majority of the rollers will be PROK HDPE, our market-leading, lightweight composite roller. PROK HDPE was chosen due to its lightweight construction and exceptional reliability. The rollers include dual-layer wear indicator technology which facilitates smarter roller maintenance.

PROK General Manager WA Wade Guelfi said PROK HDPE will bring a range of benefits to Roy Hill’s operations “PROK HDPE is proven in heavy-duty iron ore applications and will assist to reduce maintenance costs, increase production and importantly improve safety outcomes.”

“We were thrilled to be able to partner with Roy Hill on this project and look forward to working closely with them to continue to optimise conveyor performance.”

Find out more about PROK HDPE here.