Tube Diameter

127 mm to 219 mm

Bearing Sizes

6305 to 6312

Tube Material

High density polyethylene

Shaft Sizes

26mm - 62 mm

Seal Performance Testing

Testing Based on DIN 22112

Improve performance

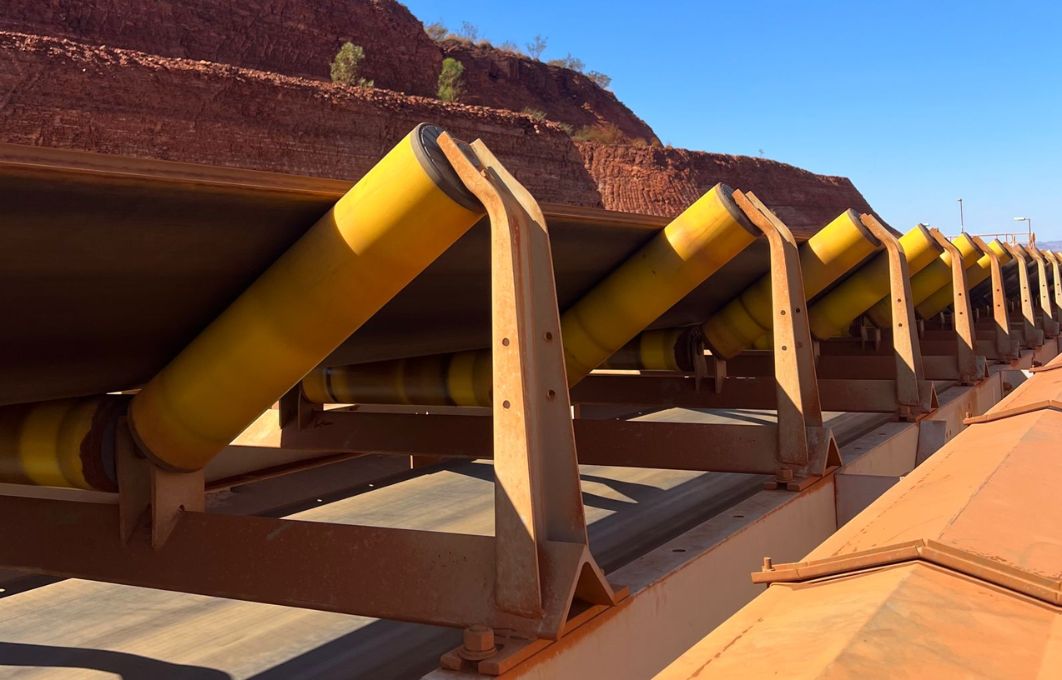

PROK HDPE is a light-weight, reliable roller designed for high-speed and large tonnage applications.

Informed by years of research and development and made from resilient polymer matrix, this innovative roller is made to last.

Improve site productivity, reduce downtime and minimise risk to your people and your belt.

HDPE Roller Features

HDPE Roller Features

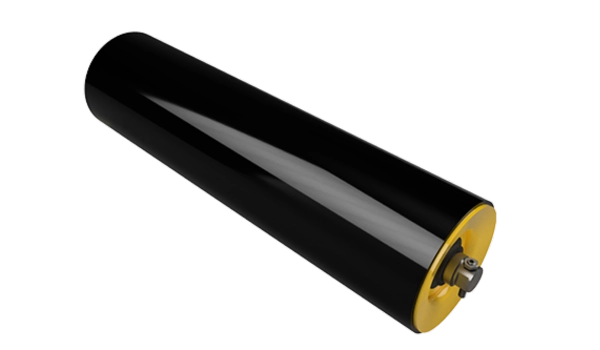

High-performance HDPE tube

A versatile substance with impressive tensile strength, the HDPE’s reinforced polymer matrix material makes a lightweight and durable roller.

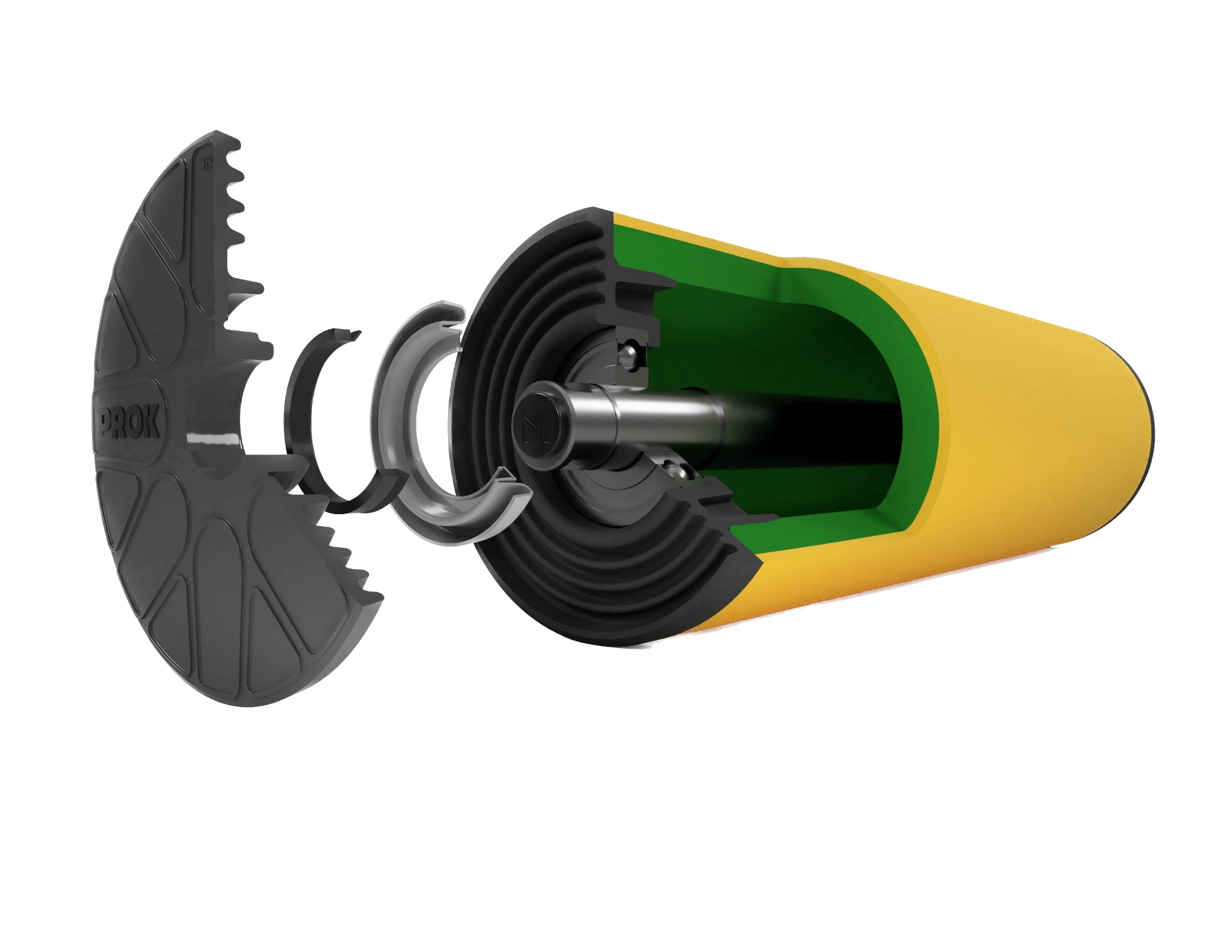

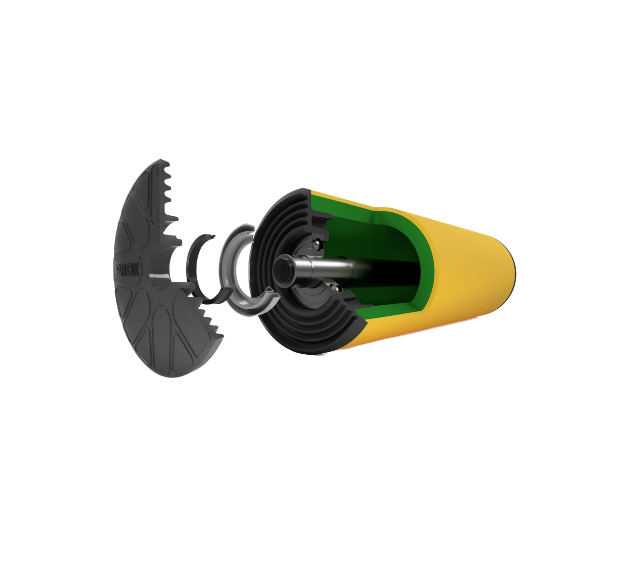

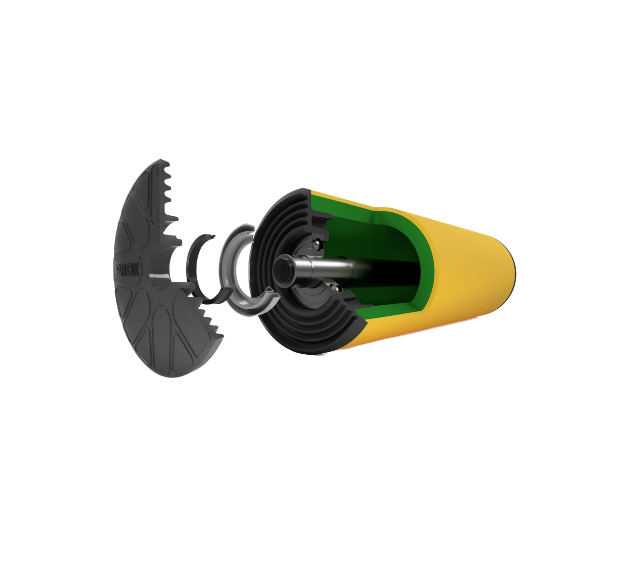

Integrated sealing design

A non-metallic housing and three-tiered sealing system with a multi-labyrinth seal and contact seal means bearings are well protected from contaminants. Independent testing shows PROK HDPE's seal achieves 6x superior performance than other composite rollers on the market.

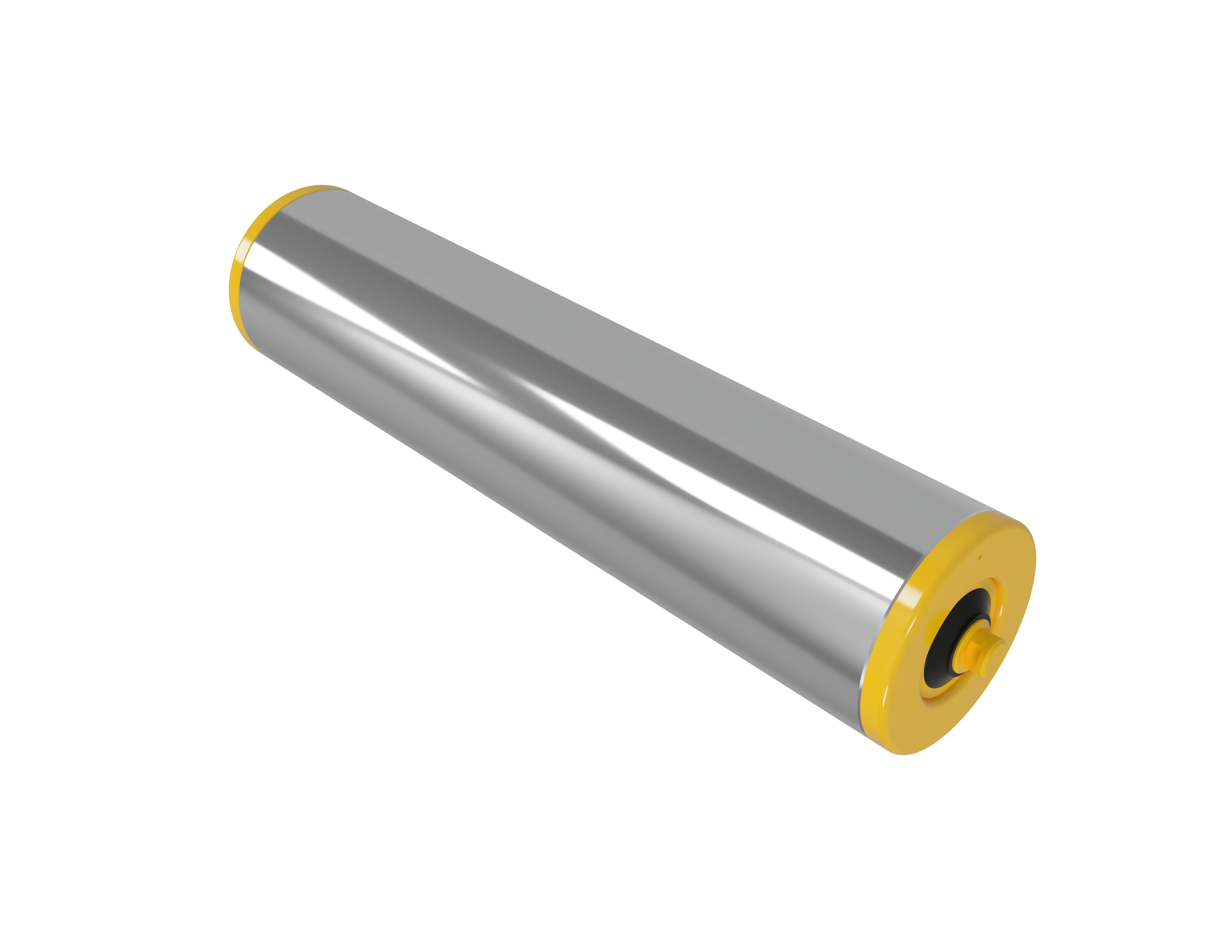

Visual wear indicator technology

Streamline conveyor roller maintenance with PROK's visual wear indicator technology. In a world first, PROK has introduced new visual wear indicator technology to the market which assists mining companies to improve maintenance planning. The Original PROK yellow tube combined with the green inner layer acts as a visual wear indicator for maintenance teams so they can better plan roller changeouts.

Friction welded bearing housing

PROK HDPE utilises friction welded bearing housings. The housing and tube are fused into one continuous material helping to transition stress and deflection. This feature eliminates the common failure mode relating to bearing housing dislodgement. The friction welded housing also creates an impenetrable seal preventing contaminants.

HDPE Roller Benefits

01

02

03

Frequently asked questions

PROK HDPE offers reduced maintenance downtime and a lower total cost of ownership, making it a smart choice for miners. It is lightweight, wear-resistant, and belt-friendly, improving efficiency and safety in heavy-duty applications.

PROK HDPE features a visual wear indicator: the Original PROK yellow tube combined with the green inner layer. When you see green, it’s a proactive maintenance tool. This indicator assists maintenance teams in planning roller changeouts, reducing the risk of unexpected failures.

Maintaining the roller shell within 5mm of wear is crucial. Experience shows that 7-9mm of shell wear significantly increases failure rates in non-metallic rollers. Beyond this threshold, localized shell wear can create stress concentrations, negatively impacting the roller’s fatigue life under cyclic loading.

PROK HDPE stands out due to its superior design, seal system, load capacity, and thermal stability. It offers improved noise levels and weight compared to other non-metallic rollers but outperforms them in terms of wear resistance and overall performance.

PROK HDPE utilizes friction welding, a robust method that ensures the roller housing remains securely attached. This prevents any risk of housing dislodgment, enhancing the roller’s durability and reliability in demanding mining applications.

PROK HDPE is specifically developed for heavy-duty mining applications where durability and reduced maintenance downtime are critical.

PROK HDPE features a three-tiered sealing system, including a multi-labyrinth seal and contact seal, which effectively protects the roller’s bearings from contaminants. This advanced sealing system minimizes the risk of bearing damage, extends the roller’s service life, and ensures reliable performance even in harsh and abrasive mining conditions. Independent testing shows PROK HDPE sealing system is 6x more superior than competitor products.

The lightweight nature of PROK HDPE rollers reduces the risk of manual handling injuries among mining personnel during installation and maintenance. By minimizing the physical strain associated with handling heavy metallic rollers, PROK HDPE promotes a safer work environment for your team. This enhanced safety aspect aligns with our commitment to ensuring the well-being of your people and reducing workplace accidents.

View more rollers

Don’t get left behind

We don’t stop chasing performance, and neither should you. Optimise your site today.