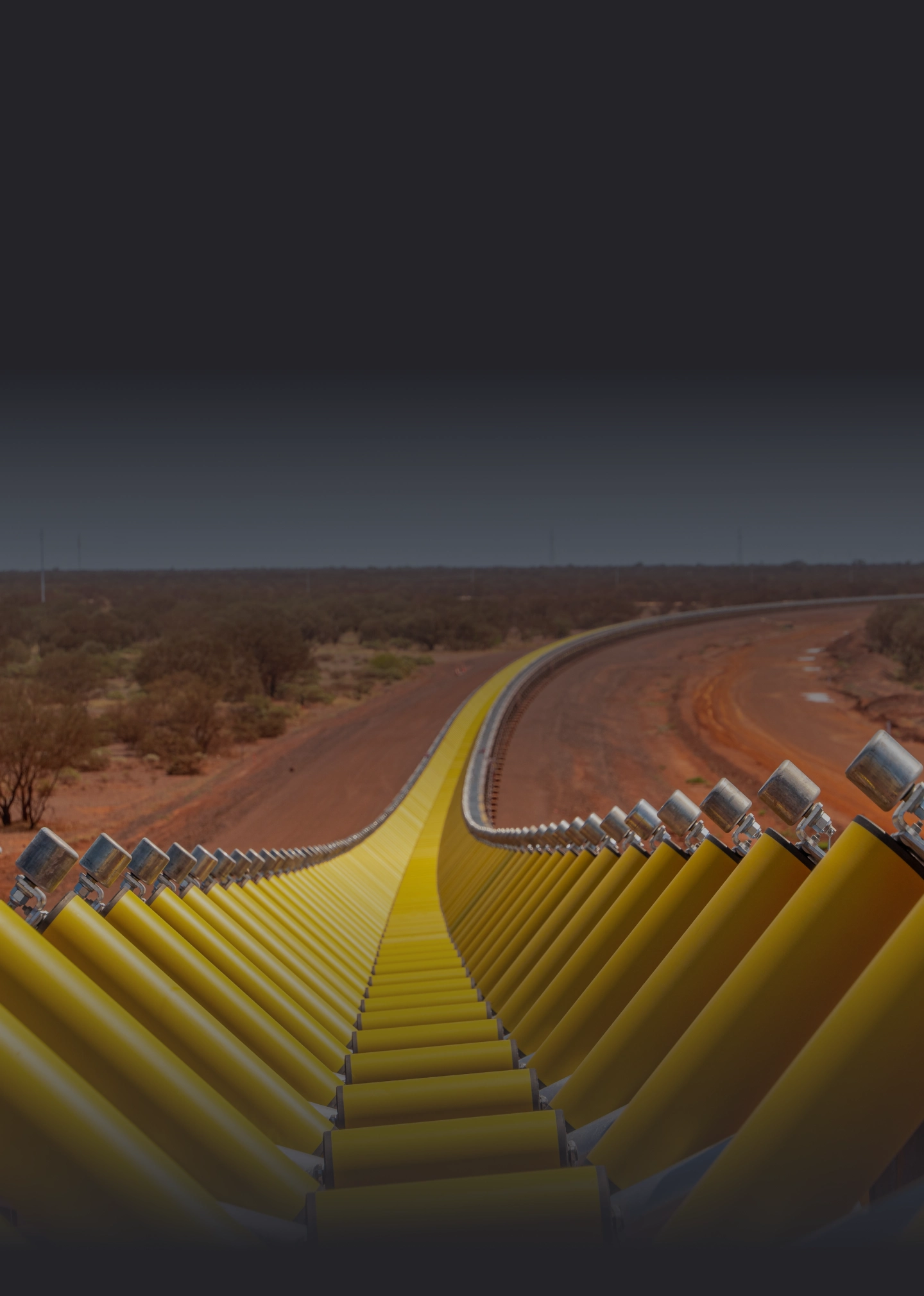

The complete conveyor experience

Delivers superior outcomes on site

So performance never stops.

Optimise my site

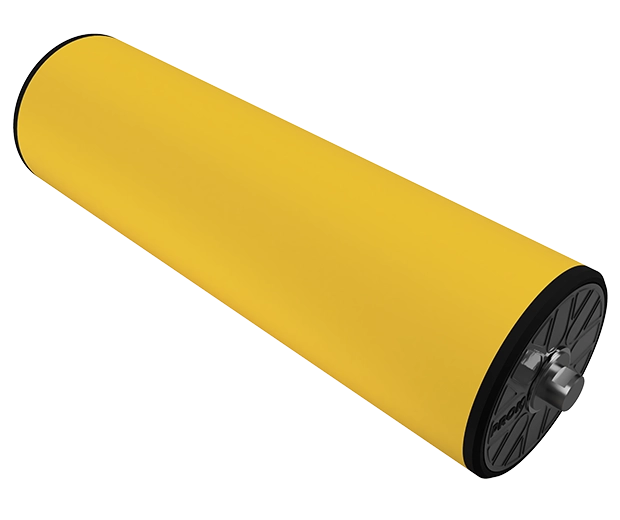

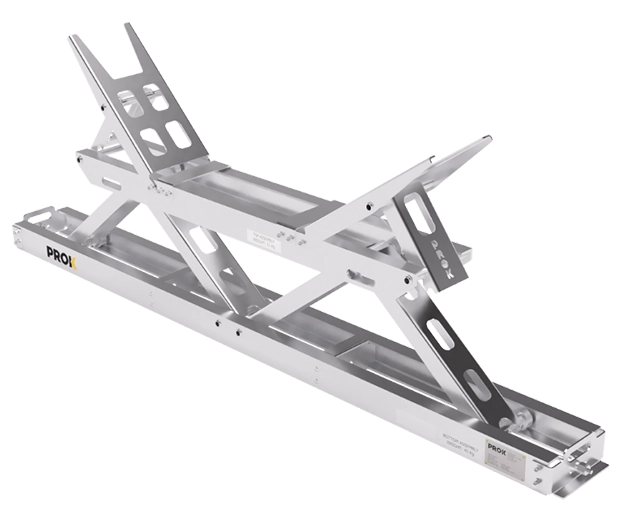

World-leading conveyor equipment technology

Improve conveyor performance

Accelerating mining globally

Manufacturing conveyor components internationally with local manufacturing facilities in Australia, Brazil, Canada, USA, Indonesia and Chile.

Title

Don’t get left behind

We don’t stop chasing performance, and neither should you. Optimise your site today.